- English

- 简体中文

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What Are Chemical Intermediates and How Are They Used in Pharmaceutical Manufacturing

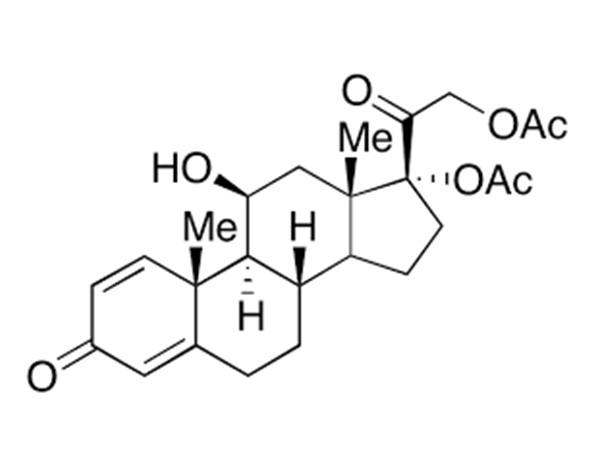

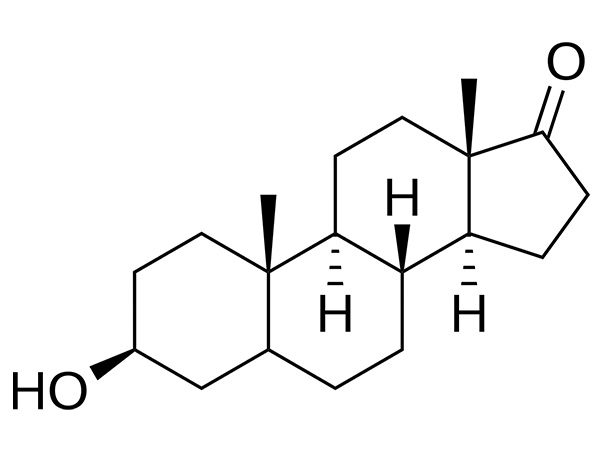

Have you ever wondered what goes on behind the scenes to create the life-saving medications we often take for granted? After two decades at the forefront of technology and innovation, I’ve learned that true breakthroughs, whether in software or pharmaceuticals, rely on foundational building blocks. In drug development, these critical components are known as chemical intermediates. They are the unsung heroes, the precise molecular stepping stones that transform basic raw materials into complex Active Pharmaceutical Ingredients (APIs). At Humanwell, our two decades of experience are dedicated to mastering these very compounds. We understand that the purity, stability, and reliability of every Intermediates Category directly determine the safety, efficacy, and scalability of the final drug. This blog will delve into the indispensable role these molecules play and how Humanwell ensures your manufacturing process is built on a foundation of excellence.

What Exactly Constitutes a Chemical Intermediate in Pharma?

In the simplest terms, a chemical intermediate is a partially processed compound that undergoes further chemical transformation before becoming the final API. Think of it like constructing a skyscraper: you don’t assemble the penthouse from raw steel and glass. First, you create prefabricated beams, panels, and modules—each meticulously engineered and tested. These modules are our intermediates. They are produced in multi-step synthesis pathways, where each step yields a new, defined Intermediates Category. The quality control at each of these stages is paramount. A single impurity or inconsistency in an early-stage intermediate can be magnified through subsequent reactions, compromising the entire batch. This is where our philosophy at Humanwell aligns perfectly with the needs of modern pharma: we provide not just chemicals, but guaranteed, documentable quality at every link in the chain.

Why Is the Sourcing of Your Intermediates Category So Critical?

I’ve witnessed countless projects where the bottleneck wasn't the final formulation, but an unreliable supply of high-purity intermediates. The pain points are real: delayed timelines, failed regulatory audits, and costly batch rejections. Sourcing your Intermediates Category is not a commodity purchase; it is a strategic partnership for your supply chain. The critical parameters go far beyond the basic chemical name. You must consider:

-

Synthetic Route Expertise: Does your supplier understand the nuances of the chosen synthesis pathway?

-

Regulatory Support: Can they provide comprehensive documentation like DMFs, CofAs, and detailed impurity profiles?

-

Consistency: Can they guarantee batch-to-batch reproducibility at scale?

At Humanwell, we build our partnerships on solving these exact challenges. We integrate our expertise directly into your development pipeline, ensuring every Intermediates Category we deliver meets the stringent standards required for a seamless journey from clinical trials to commercial production.

What Key Parameters Define a High-Quality Intermediates Category?

Evaluating an intermediate requires a deep dive into its specifications. It’s a technical blueprint that dictates its performance. Here are the non-negotiable parameters we control at Humanwell:

-

Purity and Assay: The cornerstone specification, typically required at ≥99.0% for critical steps, often measured by HPLC.

-

Impurity Profile: Identified and quantified related substances, residual solvents, and genotoxic impurities must be strictly within ICH guidelines.

-

Physical Characteristics: Crystal form, particle size distribution (PSD), and density can drastically affect downstream processing like filtration and reactivity.

-

Stability: Understanding storage conditions (temperature, humidity, light sensitivity) and shelf-life under those conditions is essential for planning.

-

Documentation: A complete Certificate of Analysis (CofA), supported by applicable Drug Master File (DMF) references, is a must for regulatory filings.

To illustrate the level of detail, let's examine a hypothetical but realistic specification table for two different Intermediates Category types:

Table 1: Typical Specification Comparison for Two Common Intermediates Categories

| Parameter | Advanced Bromo-Ketone Intermediate (Category: Chiral Building Block) | High-Purity Peptide Coupling Fragment (Category: Peptide Synthesis) |

|---|---|---|

| Purity (HPLC) | ≥ 99.5% | ≥ 98.5% |

| Chiral Purity (ee) | ≥ 99.8% | Not Applicable |

| Major Single Impurity | ≤ 0.15% | ≤ 0.5% |

| Residual Solvents | MeOH < 3000 ppm | DMF < 800 ppm |

| PSD (D90) | 50-150 μm | Subject to customer request |

| Recommended Storage | 2-8°C, under inert atmosphere | -20°C, desiccated |

How Does Humanwell Ensure Excellence Across Every Intermediates Category?

Our commitment is operationalized through a "Quality by Design" approach embedded in our manufacturing. For us, excellence isn’t an inspection point; it’s engineered into the process. We employ state-of-the-art analytics like LC-MS, NMR, and chiral HPLC for characterization. Our processes are scalable and validated, ensuring the gram-scale purity you see in development is faithfully reproduced at the ton-scale for commercial supply. We manage a diverse portfolio of Intermediates Category solutions, from complex chiral synthons to standard aromatic derivatives, each produced under the same rigorous quality management system. This holistic control is what allows us to be a true extension of your R&D and manufacturing teams.

What Are the Common Applications in Drug Synthesis?

Intermediates are versatile and find application across the entire spectrum of modern therapeutics. Their use defines the efficiency of the synthesis.

Table 2: Application of Different Intermediates Categories in Target API Synthesis

| Intermediates Category | Primary Role in Synthesis | Common Target API/Therapeutic Area |

|---|---|---|

| Chiral Intermediates | Introducing specific 3D stereochemistry crucial for biological activity. | SSRIs (Antidepressants), ACE Inhibitors (Hypertension), Antiviral agents. |

| Peptide Fragments | Enabling solid-phase or solution-phase coupling for complex biopolymers. | GLP-1 Analogs (Diabetes), Oncology peptides. |

| Heterocyclic Building Blocks | Forming the core scaffold of many small molecule drugs. | Kinase Inhibitors (Oncology), Antifungals, Antibiotics. |

| Advanced Protected Synthons | Allowing selective reactivity in multi-functional molecules. | Complex natural product derivatives, Oncology payloads. |

Frequently Asked Questions on Intermediates Category

Navigating the world of chemical intermediates can bring up technical questions. Here are some detailed answers to common queries we receive at Humanwell.

FAQ 1: How do you ensure batch-to-batch consistency for a custom Intermediates Category?

We implement a robust Process Analytical Technology (PAT) framework. Critical process parameters (CPPs) like temperature, pressure, and pH are monitored in real-time. Each batch is validated against a stringent control strategy derived from our Quality by Design (QbD) principles, ensuring that all Critical Quality Attributes (CQAs) are met consistently before release.

FAQ 2: What regulatory documentation can you provide with your Intermediates Category products?

For every Intermediates Category, we provide a comprehensive Certificate of Analysis (CofA) that details all tested parameters and results. We can also support regulatory submissions with Type II Active Substance Master Files (ASMFs) or Drug Master Files (DMFs) for qualified products, detailing the manufacturing process, quality controls, and impurity profiles to aid in your regulatory approval process.

FAQ 3: Can you scale up a custom Intermediates Category from lab scale to commercial production?

Absolutely. Our integrated development and manufacturing teams work in parallel from the outset. We design scalable synthetic routes, identify and control critical scale-up parameters early, and utilize pilot plants to bridge the gap between laboratory and full-scale production, ensuring a smooth, reliable, and cost-effective transition for your project.

How Can You Transform Your Pipeline with the Right Partnership?

The journey from molecule to medicine is fraught with complexity. The choice of partner for your chemical intermediates is one of the most decisive factors for success. It’s a choice between managing constant uncertainty and having a foundation of unwavering reliability. At Humanwell, we’ve spent twenty years refining our ability to be that foundation. We don’t just supply chemicals; we deliver confidence, backed by data, expertise, and a partnership mindset.

Are you ready to build your next breakthrough on a foundation of proven quality and expertise? Contact us today to discuss your specific Intermediates Category needs. Let our team of experts provide you with a detailed quote and show you how the Humanwell difference can streamline your development timeline, de-risk your manufacturing, and help bring vital therapies to the world faster. Visit our website or email our technical sales team to start the conversation.