- English

- 简体中文

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What are the categories of pharmaceutical intermediates?

In the pharmaceutical industry chain, pharmaceutical intermediates are key precursors for synthesizing active pharmaceutical ingredients (APIs). They directly reflect the technical routes and therapeutic area distribution of drug R&D. These compounds are prepared via specific chemical reactions. Then, they go through steps like condensation, acylation, and chiral synthesis to become APIs. The quality and supply stability of pharmaceutical intermediates affect drug production efficiency. Here is a breakdown of their classification system and industry applications from four major dimensions.

Classification by therapeutic area: Targeted demand for precise positioning

Antitumor intermediates are the fastest-growing category in recent years. For instance, the synthesis of PD-1 inhibitor intermediates requires multiple coupling reactions, such as 2-fluoro-5-chlorobenzoic acid as a key intermediate for the preparation of immune drugs like camrelizumab. For the ALK target, the brigatinib intermediate needs to construct a biphenyl structure through a Suzuki coupling reaction, with a purity requirement of over 99.5%.

Antimicrobial intermediates cover antibiotics, antivirals, and other fields. For example, 7-aminocephalosporanic acid (7-ACA), as the core intermediate for cephalosporin drugs, is obtained through the cleavage of cephalosporin C; the chiral amine structure of the HIV drug intermediate ritonavir requires the use of enzymatic resolution technology for preparation.

Cardiovascular intermediates are represented by statin drug intermediates, such as the atorvastatin intermediate (3R,5R)-dihydroxy heptanoic acid lactone, which requires an asymmetric hydrogenation reaction to build a chiral center, with an optical purity of over 99% e.g.

Classification by chemical structural characteristics: Scientific division of molecular skeletons

Heterocyclic intermediates account for half of the pharmaceutical intermediates, with nitrogen-containing heterocycles being the most common. For example, pyrrolopyridine intermediates are used in the synthesis of JAK inhibitors, piperazine intermediates (such as 1-tert-butoxycarbonyl piperazine) are common structural units in psychotropic drugs, and purine intermediates are widely used in antiviral drugs (such as acyclovir).

Chiral intermediates have high technical barriers due to the control of stereochemistry. For instance, the (S)-configuration intermediate of thalidomide needs to be prepared through chiral source synthesis or kinetic resolution, and its optical purity directly affects drug safety. In recent years, the application of continuous flow chiral catalysis technology has reduced the production cost of such intermediates by more than 30%.

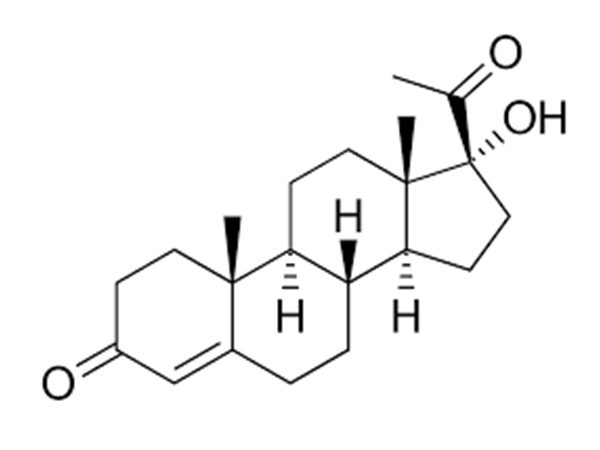

Steroidal intermediates are obtained by modifying natural steroidal compounds, such as the prednisolone intermediate prepared from diosgenin, which requires multiple reactions such as oxidation and hydrolysis. The maintenance of the configuration of the steroidal nucleus is the key to the synthesis.

Classification by synthesis stage and value: Clear definition of the industrial chain hierarchy

Starting intermediates are mostly derived from basic chemical raw materials, such as p-nitroaniline obtained by nitrating aniline, which is used as the starting material for sulfonamide drugs and has an abundant market supply with small price fluctuations.

Key intermediates refer to the core steps in the synthesis route that determine the formation of the drug's active group. For example, the key intermediate cyclopentenecarboxylic acid of oseltamivir requires the construction of a six-membered ring structure through a Diels-Alder reaction, with a high synthesis complexity and a single-kilogram price that can be 5-10 times that of ordinary starting intermediates.

Customized intermediates are tailored for innovative drug research and development. For instance, the linker intermediate of a certain ADC drug needs to meet characteristics such as resistance to enzymatic hydrolysis and cleavability, often using special processes such as solid-phase synthesis or fluorination modification. The production scale usually starts at the gram level, and the research and development cycle can last 12-18 months.

Classification by production technology path: Directional guidance for process innovation

Chemical synthesis intermediates remain the mainstream. For example, Grignard reagent intermediates prepared through the Grignard reaction are used to build carbon-carbon bonds; the application of electrochemical synthesis technology has reduced the energy consumption of nitrobenzene reduction to prepare aniline intermediates by 20%. Biocatalytic intermediates have significant advantages in chiral synthesis. For instance, the use of transaminase to catalyze the preparation of sitagliptin intermediates achieves an atom economy of 100%, reducing the use of organic solvents by 90% compared to chemical methods. Green catalytic intermediates adopt technologies such as continuous flow reactions and solvent-free synthesis. For example, a certain sartan drug intermediate is synthesized through microwave-assisted synthesis, shortening the reaction time from 8 hours in the traditional batch method to 20 minutes and reducing wastewater by 75%.

As the development of innovative drugs advances towards complex targets, pharmaceutical intermediates are evolving towards higher activity and selectivity. When selecting intermediates, enterprises need to pay attention to the ICH Q3A impurity control guidelines. The application of new technologies such as flow chemistry and photocatalysis will drive the production of intermediates towards "high efficiency, green, and intelligent", providing stronger support for the consistency evaluation of generic drugs and the research and development of innovative drugs.